Sale OEM Traditional Sanitary Ware Products Manufacturer

The bathroom is a sanctuary within the home, a space where quality and functionality are essential. Sanitary ware manufacturers play a crucial role in delivering products that meet these needs. From toilets and sinks to faucets and showers, each item must be designed and produced with higher standards of quality. This article will explore the various methods and processes a sanitary ware manufacturer employs to ensure that their bathroom products are of quality.

A sanitary ware manufacturer begins the journey to quality with the design phase. By focusing on ergonomics, aesthetics, and functionality, they create products that not only look good but also serve their intended purpose effectively. Designers at these manufacturers consider the end-user experience, ensuring that their products are user-friendly and meet the demands of modern bathroom design.

The choice of materials is a critical aspect of quality assurance for a sanitary ware manufacturer. High-quality materials such as vitreous china, stainless steel, and brass are selected for their durability, resistance to corrosion, and ability to maintain a pristine appearance over time. These materials are also chosen for their ease of cleaning and maintenance, which is essential for products that are frequently exposed to water and humidity.

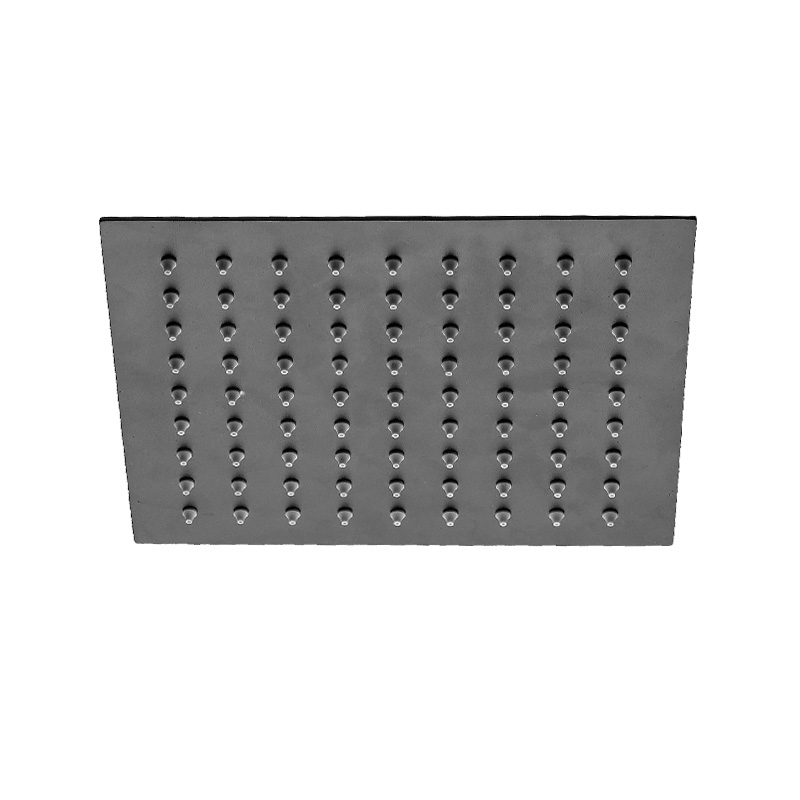

The manufacturing process is where a Sale Traditional Sanitary Ware truly demonstrates its commitment to quality. Advanced machinery and advanced technology are employed to shape, mold, and finish products with precision. This ensures that each item is uniform in size, shape, and finish, meeting the strict quality control standards set by the manufacturer.

Throughout the production process, a sanitary ware manufacturer conducts rigorous quality control checks. These checks are designed to identify any defects or inconsistencies in the products at various stages of production. By implementing a systematic approach to quality control, manufacturers can quickly address any issues, reducing the likelihood of defective products reaching the market.

Before a sanitary ware manufacturer releases their products to the market, they undergo a series of tests to ensure compliance with industry standards and regulations. These tests may include durability tests, water efficiency tests, and safety tests. Certifications from recognized bodies provide an additional layer of assurance to consumers that the products they purchase meet higher quality standards.

A commitment to continuous improvement is a hallmark of OEM Sanitary Ware Products. They invest in research and development to stay abreast of the new trends and technologies in the industry. This enables them to continually innovate and improve their products, ensuring they remain competitive and relevant in the market.

Listening to customer feedback is another way a sanitary ware manufacturer ensures quality. By taking into account the experiences and suggestions of end-users, manufacturers can make necessary adjustments to their products. This feedback loop helps to refine the design and functionality of bathroom products, ensuring that they meet the needs and expectations of consumers.

In today's market, sustainability is a key concern for many consumers. A responsible sanitary ware manufacturer takes this into account by using eco-friendly materials and processes that reduce waste and reduce the environmental impact of their operations. This not only contributes to a cleaner environment but also aligns with the growing demand for green products.

The workforce at a sanitary ware manufacturer is a critical component of quality assurance. By providing ongoing training and skill development, manufacturers ensure that their employees are equipped with the knowledge and expertise to produce high-quality products. This investment in human capital results in a more skilled and efficient workforce, which in turn results in better products.

In conclusion, a sanitary ware manufacturer's commitment to quality is evident in every aspect of their operations, from design and materials selection to manufacturing processes and customer feedback. By adhering to strict quality control measures, investing in continuous improvement, and prioritizing sustainability, these manufacturers ensure that their bathroom products are of a higher caliber. This dedication to quality not only satisfies consumers but also positions the manufacturer as a pioneer in the industry, setting the standard for others to follow.

English

English 中文简体

中文简体 عربى

عربى Español

Español